The Future of Steel Fabrication: Technological Advancements to Watch

New Technology in Steel

Apr 21, 2024

New Technology in Steel

Key Takeaways:

Technological advancements in steel fabrication promise increased efficiency, precision, and sustainability.

Automation and AI are set to revolutionize traditional fabrication methods.

Staying informed about these trends is crucial for industry professionals and companies like TratFab, leading the way in innovation in Star, Idaho.

In the ever-evolving landscape of steel fabrication, technological advancements stand at the forefront of industry transformation. At TratFab, nestled in the industrious heart of Star, Idaho, we're not just witnesses to this change; we're participants, driving forward with innovation that promises to redefine what's possible in steel fabrication.

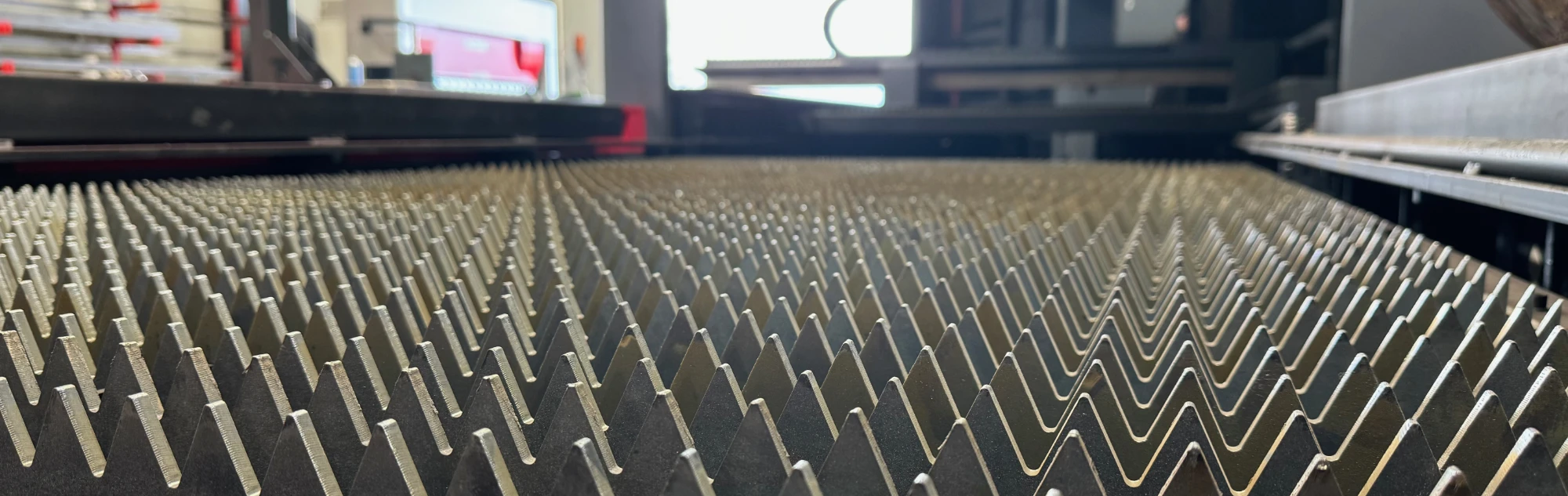

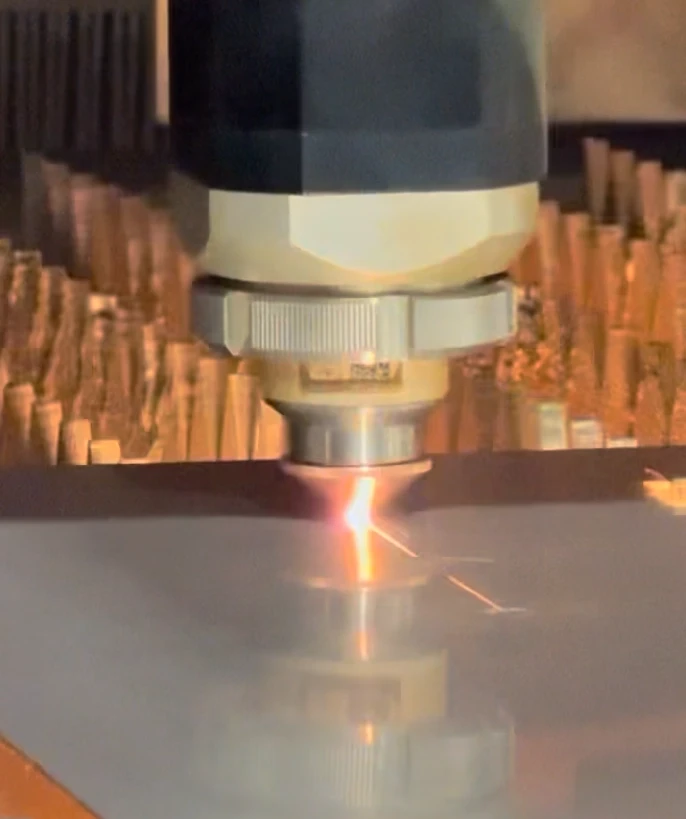

The Dawn of Automation

The introduction of automation into steel fabrication marks a significant leap towards efficiency and precision. Automated cutting machines, robotic arms, and CNC (Computer Numerical Control) technology have started to replace manual processes, reducing human error and speeding up production times. The future looks even brighter, with advancements focusing on fully automated fabrication lines that promise seamless production from design to finished product.

AI and Machine Learning: A New Era of Fabrication

Artificial Intelligence (AI) and Machine Learning are not just buzzwords; they're the backbone of the next major shift in steel fabrication. These technologies offer unprecedented capabilities in predicting material behavior, optimizing production processes, and even conducting real-time quality assurance checks. The ability to learn and adapt makes AI an invaluable asset in pushing the boundaries of steel fabrication.

3D Printing: Sculpting the Future

3D printing in steel fabrication, also known as additive manufacturing, is set to revolutionize the way we think about constructing with steel. From complex architectural structures to bespoke components, 3D printing offers a level of design freedom and customization previously unimaginable. This technology not only opens new avenues for creativity but also promises significant reductions in waste and production time.

Sustainability and Eco-Friendly Practices

As the global emphasis on sustainability grows, the steel fabrication industry is not left behind. Technological advancements are increasingly focused on eco-friendly practices, from the use of recycled materials to energy-efficient manufacturing processes. Innovations in this area not only contribute to a healthier planet but also offer cost efficiencies for fabrication companies.

Virtual Reality: A New Dimension in Fabrication Planning

Virtual Reality (VR) technology is transforming the planning and design stages of steel fabrication. By creating immersive 3D models, engineers and designers can explore structural designs in a virtual environment, identifying potential issues and making adjustments before physical production begins. This not only saves time and resources but also enhances the safety and accuracy of the final product.

FAQs

Q: How is TratFab integrating these technological advancements?

A: TratFab is at the forefront of integrating cutting-edge technologies like automation into our operations, ensuring we stay ahead in delivering efficient, precise, and innovative steel fabrication solutions.

Q: Can automation and AI really improve the quality of steel fabrication?

A: Absolutely. Automation reduces human error, while AI can optimize production processes and perform quality checks, collectively enhancing the overall quality of fabrication.

Q: Are these technologies making steel fabrication more expensive?

A: While initial investments in new technologies may be high, the long-term benefits of reduced production times, decreased waste, and improved efficiency can actually lower costs.

Q: How can I learn more about TratFab's services and innovations?

A: Visit our website at Tratfab.com or call us directly at 208-571-5301 to discover how TratFab is leading the steel fabrication industry into the future with innovative practices and technologies.

As steel fabrication sails into the future, TratFab is excited to be at the helm, steering towards a horizon filled with promise, efficiency, and innovation. With our eyes set on technological advancements, we're not just building structures; we're shaping the future of our industry. Join us as we embark on this exciting journey, crafting the world of tomorrow with the steel of today.