Menu

Safety Protocols in Steel Fabrication You Should Know

Steel Fabrication Safety Protocols

Apr 3, 2024

Safety Protocols in Steel Fabrication You Should Know

Key Takeaways:

Safety in steel fabrication is paramount to prevent workplace injuries and ensure project success.

Understanding and implementing industry-standard safety protocols can significantly reduce risks.

TratFab prioritizes safety through rigorous training, the use of protective gear, and adherence to safety regulations.

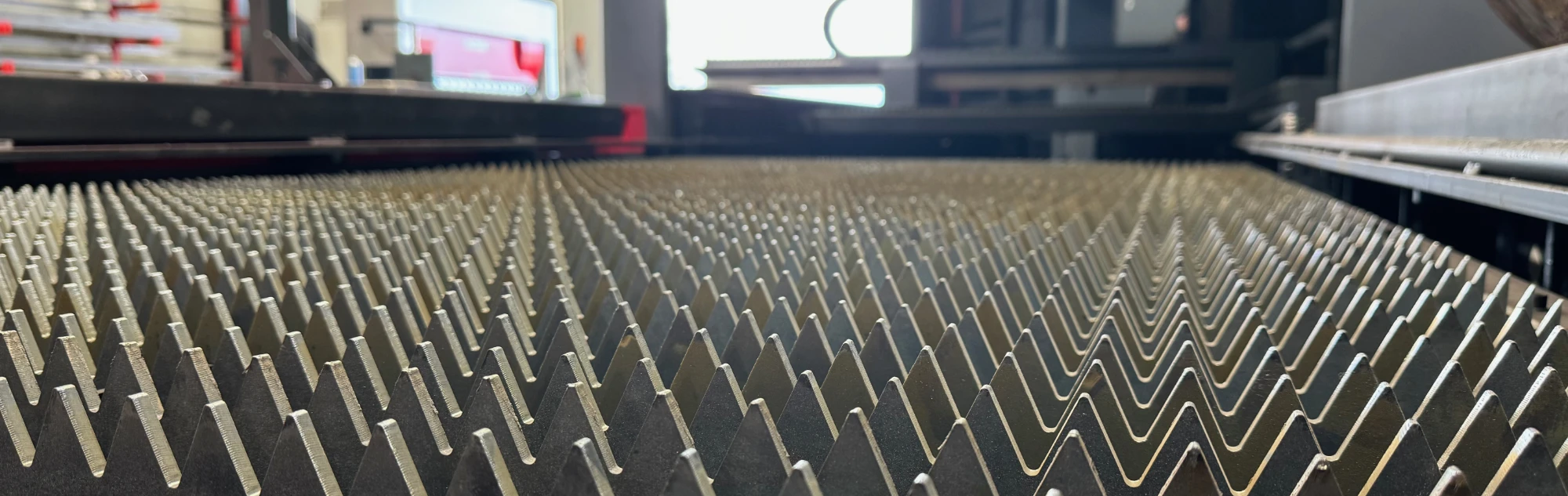

In the heart of Star, Idaho, where the steel frames of the future are welded together, safety stands as the cornerstone of every project undertaken by TratFab. As leaders in steel fabrication, we're not just committed to delivering precision and quality; we're dedicated to ensuring that every piece of steel is handled with the utmost care for safety. Here's what you need to know about the safety protocols that guide our work at TratFab.

A Culture of Safety

Safety in steel fabrication isn't just about following rules; it's about cultivating a culture where every team member is an advocate for safety. At TratFab, safety training is the foundation of our operations, ensuring that every technician, engineer, and staff member understands their role in maintaining a safe working environment.

Essential Safety Protocols in Steel Fabrication

Personal Protective Equipment (PPE): The use of PPE is non-negotiable. From helmets and goggles to gloves and safety shoes, every piece of gear is designed to protect our team from the hazards inherent in steel fabrication.

Machine Guarding: Our equipment is fitted with guards to prevent contact with moving parts, reducing the risk of injuries from machinery.

Proper Ventilation: Welding and cutting steel produce fumes that can be harmful if inhaled. Our facilities are equipped with ventilation systems to ensure clean air, preventing respiratory hazards.

Fire Safety: Given the sparks and heat involved in fabricating steel, we adhere to strict fire safety protocols, including having fire extinguishers readily available and conducting regular fire drills.

Fall Prevention: Working with steel often involves elevated platforms. TratFab implements fall prevention measures, including safety harnesses and railings, to protect our team from falls.

Investing in Training and Awareness

At TratFab, we believe that the most effective safety equipment is knowledge. Regular training sessions and safety briefings keep our team updated on the best practices and latest advancements in safety technologies.

Creating Safe Spaces

Beyond personal safety, we're committed to maintaining facilities that are hazard-free. Regular inspections, maintenance of equipment, and cleanliness are part of our daily routine, ensuring a safe and productive workspace.

FAQs

Q: What is the most common safety hazard in steel fabrication? A: The most common hazards include cuts and lacerations from sharp metal, burns from welding, and respiratory issues from inhaling fumes. Proper PPE and ventilation mitigate these risks.

Q: How does TratFab stay updated on safety protocols? A: We stay informed through industry associations, safety training programs, and continuous learning initiatives to ensure our protocols meet or exceed industry standards.

Q: Can I visit the TratFab facilities to see your safety measures firsthand? A: Absolutely! We welcome visits to our Star, Idaho facility. Please call us at 208-571-5301 to arrange a tour and see our safety protocols in action.

Q: How does TratFab involve its employees in maintaining safety? A: We encourage a culture of safety where every employee is empowered to speak up about hazards and participate in safety planning and review processes.

At TratFab, safety is not just a protocol; it's a promise—a promise to our team, our clients, and our community in Star, Idaho. It's the assurance that every project we undertake is built on a foundation of safety, precision, and excellence. For more information on our commitment to safety or to discuss your next project, visit us at Tratfab.com or give us a call at 208-571-5301. Safety in steel fabrication is not just our priority; it's our legacy.