Understanding the Steel Fabrication Process: A Comprehensive Guide

Steel Fabrication Process

Apr 2, 2024

Understanding the Steel Fabrication Process: A Comprehensive Guide

Key Takeaways:

Steel fabrication involves cutting, bending, and assembling steel to create structures.

Precision, expertise, and quality control are pivotal throughout the fabrication process.

TratFab specializes in providing custom steel fabrication solutions in Star, Idaho, with unmatched precision and quality.

Steel fabrication is an intricate and sophisticated process that transforms raw steel into predefined shapes and sizes, ready for assembly and construction. At TratFab, located in the heart of Star, Idaho, we pride ourselves on our comprehensive understanding of this process, delivering custom fabrication solutions that meet the highest standards of quality and precision.

The Journey from Concept to Creation

The steel fabrication process begins with the conceptualization phase, where the vision of the final structure is mapped out. This is followed by a detailed design phase, often involving CAD (Computer-Aided Design) models to simulate and plan the fabrication process accurately.

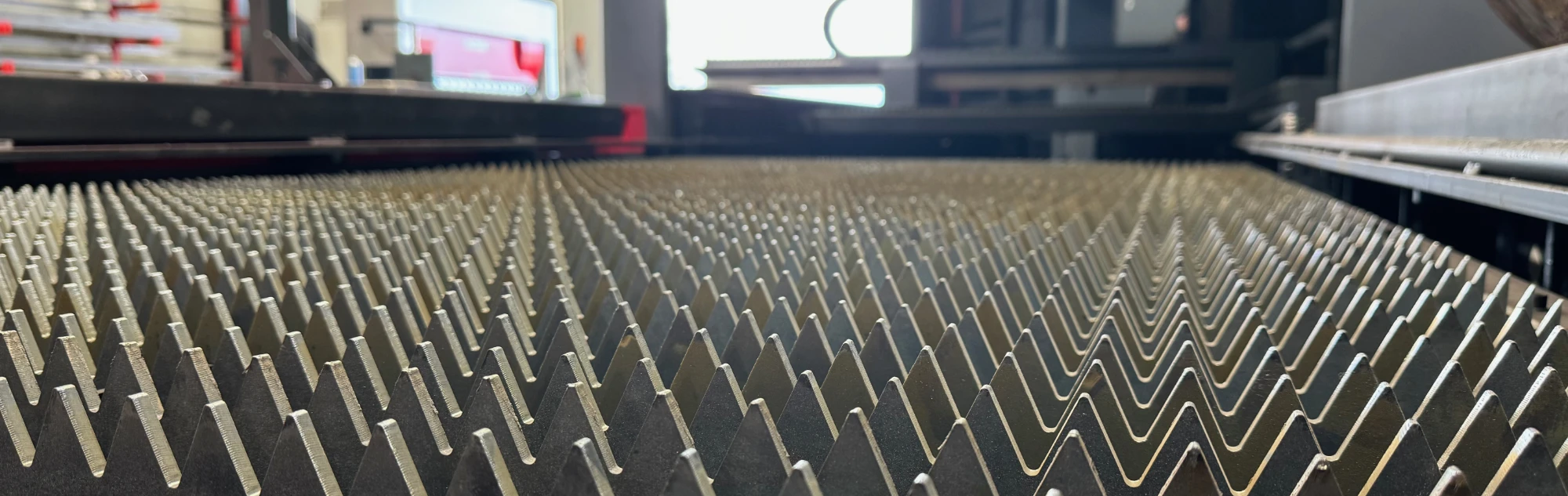

Cutting: The First Cut is the Deepest

One of the first steps in steel fabrication is cutting. Modern technology, including laser cutting, plasma cutting, and waterjet cutting, allows for precise cuts that are essential for the accuracy of the final product. At TratFab, we utilize the latest cutting technologies to ensure that every piece of steel meets our rigorous standards.

Bending: Shaping the Future

Following cutting, the steel pieces often need to be bent into shape. This is done using press brakes and other specialized machinery, capable of bending steel without compromising its strength or integrity. Our skilled technicians at TratFab expertly manage this process, ensuring every bend meets the project's specifications.

Assembling: Bringing It All Together

Assembly is where the magic happens, bringing individual pieces together to form the final structure. This often involves welding, as well as the use of bolts and rivets. Our team's attention to detail ensures that the assembly process is executed with precision, leading to the completion of structures that stand the test of time.

Quality Control: Our Promise to You

Quality control is integral to the steel fabrication process. At TratFab, each phase of fabrication is subjected to stringent quality checks, ensuring that every component we produce meets our high standards and your expectations.

FAQs

Q: Can TratFab handle large-scale projects? A: Absolutely. Our facility in Star, Idaho, is equipped to handle large-scale steel fabrication projects, with a team skilled in managing and executing complex assignments.

Q: What types of steel fabrication services does TratFab offer? A: We offer a comprehensive range of services, including laser cutting, bending, welding, and assembly. Our team can handle everything from structural steel fabrication to custom projects.

Q: How does TratFab ensure the quality of its fabricated steel? A: Quality control is paramount at TratFab. We conduct thorough inspections at every stage of the fabrication process, adhering to strict quality standards to ensure the excellence of our products.

Q: How can I get a quote for my steel fabrication project? A: Getting a quote is easy! Simply call us at 208-571-5301 or visit Tratfab.com. Our team will be happy to discuss your project and provide a detailed quote.

In conclusion, steel fabrication is a meticulous process that requires precision, expertise, and strict quality control. At TratFab in Star, Idaho, we are committed to providing our clients with custom steel fabrication solutions that embody these principles. Contact us today to bring your project to life with the skill and precision it deserves.