Welding Techniques in Steel Fabrication: An Overview

Welding Steel

May 4, 2024

Welding Basics

Key Takeaways:

Welding is a fundamental aspect of steel fabrication, crucial for constructing durable and reliable structures.

TratFab employs a variety of welding techniques to cater to different project requirements in Star, Idaho, and the broader Pacific Northwest region.

Understanding the strengths and applications of each welding method can significantly enhance project outcomes.

Welding Techniques in Steel Fabrication: An Overview

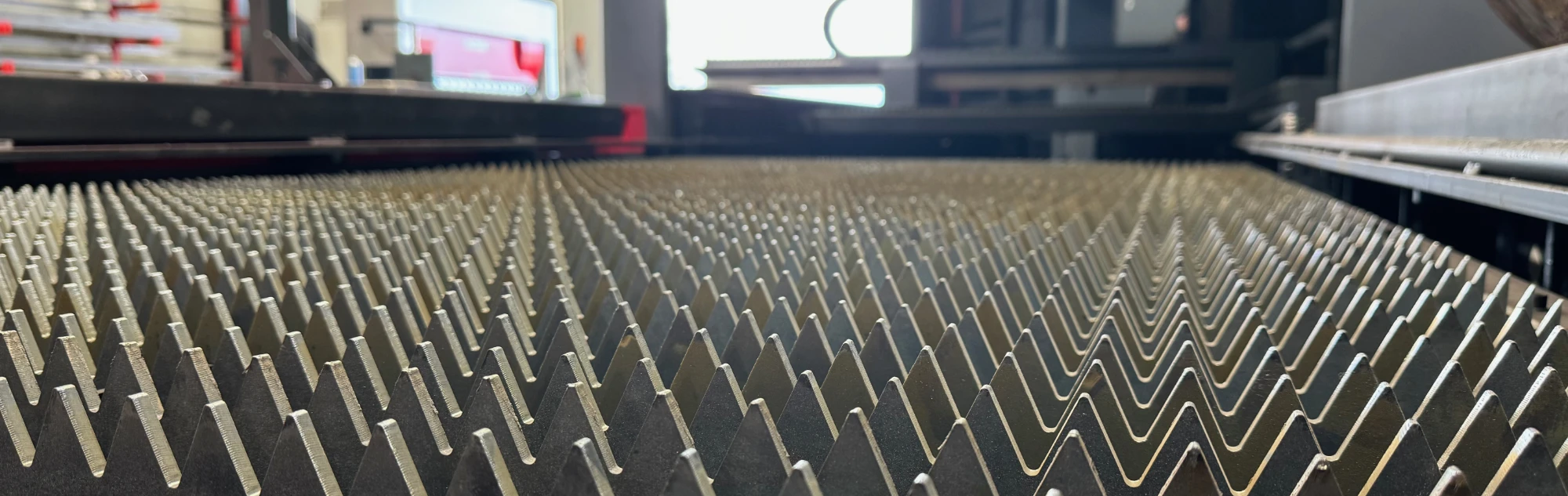

In the world of steel fabrication, welding holds a place of critical importance. It's the process that transforms individual pieces of metal into a cohesive, structurally sound whole. At TratFab, located in the scenic landscape of Star, Idaho, we pride ourselves on our mastery of various welding techniques, each offering unique benefits to our clients in Boise, Meridian, Nampa, Caldwell, and the vast expanse of the Treasure Valley and Pacific Northwest. Here’s an insight into the world of welding techniques we harness in our projects.

MIG Welding: Versatility and Efficiency

Metal Inert Gas (MIG) welding, also known as Gas Metal Arc Welding (GMAW), is prized for its versatility and efficiency. It’s ideal for a wide range of applications, from thin sheet metal work to heavier steel structures. MIG welding is characterized by its use of a consumable wire electrode and a shielding gas, creating strong, clean welds. This method is a staple at TratFab for its speed and adaptability, making it a go-to for many of our projects.

TIG Welding: Precision and Aesthetics

Tungsten Inert Gas (TIG) welding, or Gas Tungsten Arc Welding (GTAW), stands out for its precision. It allows for greater control over the weld than most other methods, making it perfect for tasks requiring meticulous detail or where aesthetics are paramount. TIG welding is especially suited for thin materials and complex shapes. At TratFab, we utilize TIG welding when working on projects that demand the highest levels of craftsmanship and visual appeal.

Stick Welding: Durability and Simplicity

Stick welding, or Shielded Metal Arc Welding (SMAW), is one of the oldest and most widely used welding techniques. Known for its simplicity and the robustness of its welds, stick welding is highly effective for outdoor projects or in environments where precision conditions can’t be controlled. Its versatility and durability make it a valuable technique in our repertoire, particularly for structural and industrial applications.

FAQs

Q: Which welding technique is best for my project?

A: The best technique depends on your project’s specific needs, including material thickness, application, and environmental conditions. TratFab’s experts can help determine the most suitable method for your project.

Q: Does TratFab offer mobile welding services?

A: Yes, TratFab provides mobile welding services, bringing our expertise directly to your site for convenience and efficiency.

Q: How does TratFab ensure the quality of its welds?

A: We adhere to strict quality control protocols, including pre-weld inspections, continuous monitoring during the welding process, and thorough post-weld inspections.

Q: Can I visit TratFab to discuss my project’s welding needs?

A: Absolutely! We welcome you to visit our facility in Star, Idaho, or contact us at 208-571-5301. You can also find more information on our website, Tratfab.com.

Welding techniques play a crucial role in steel fabrication, each with its specific advantages and applications. At TratFab, our expertise spans across various welding methods, ensuring that we can adapt to any project requirement, delivering durability, precision, and beauty. Whether you’re in Star, Boise, Meridian, Nampa, Caldwell, or anywhere in the Treasure Valley and Pacific Northwest, we’re ready to bring your steel fabrication projects to life with unmatched quality and service.