Why Does CNC Laser Cutting Matter to You?

Computer Numerical Contol Laser Cutting.

Apr 3, 2024

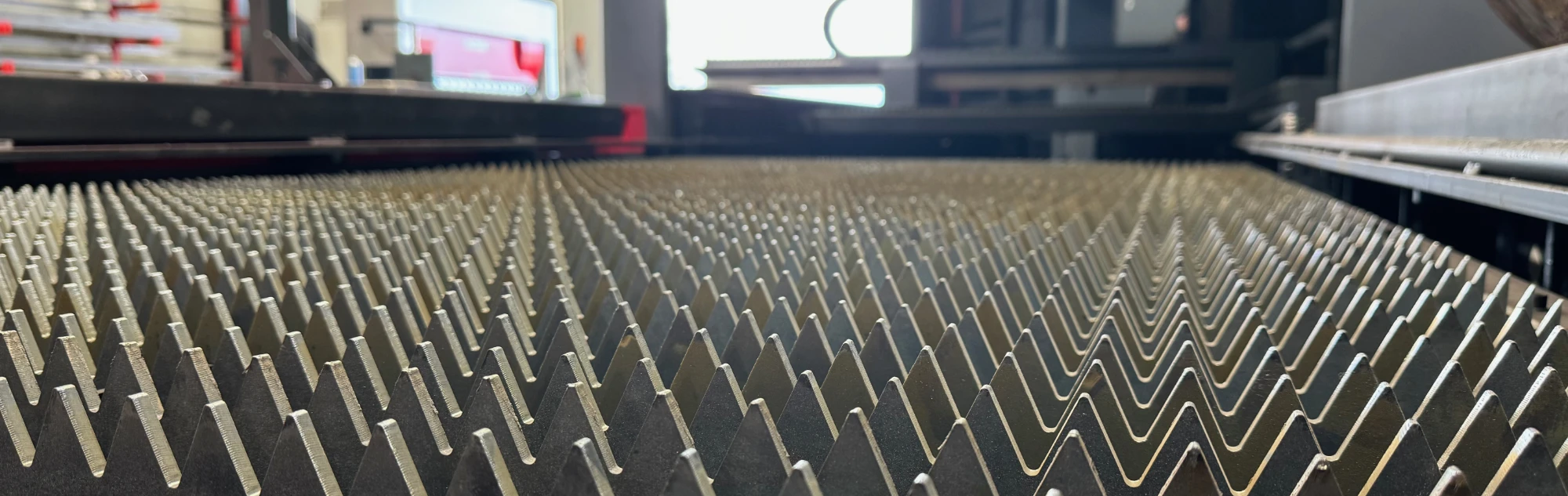

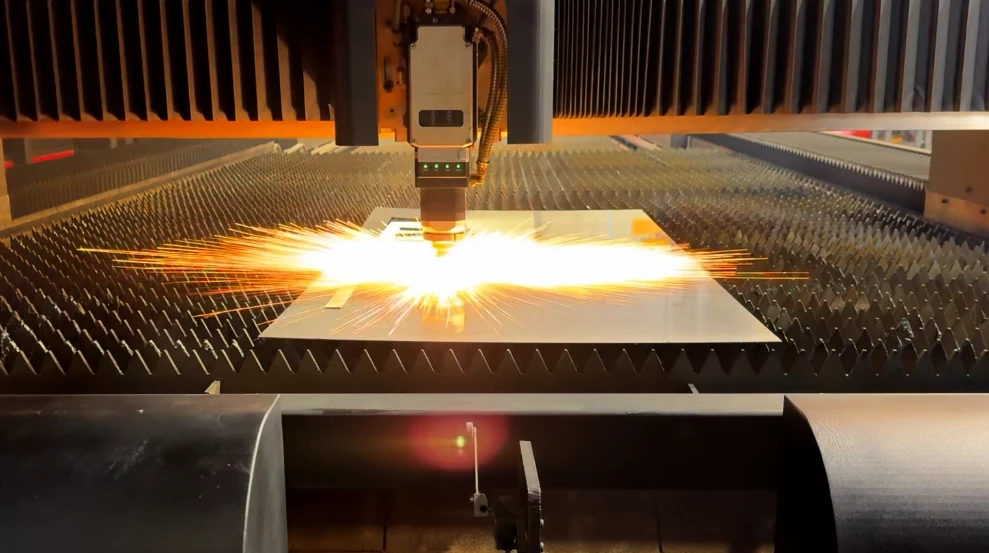

CNC (Computer Numerical Control) laser cutting plays a crucial role in steel fabrication, revolutionizing the industry with its precision, efficiency, and versatility. This technology has become indispensable for several reasons:

Unmatched Precision and Accuracy:

CNC laser cutting uses a focused laser beam to cut steel, allowing for incredibly precise cuts down to a fraction of a millimeter. This level of accuracy is essential for complex designs and tight tolerances required in many engineering and manufacturing projects, ensuring components fit together perfectly without the need for extensive rework.

High Efficiency and Speed:

Compared to traditional mechanical cutting methods, CNC laser cutting is significantly faster, enabling high-volume production runs to be completed in shorter time frames. This speed does not compromise the quality of the cut, maintaining high precision across large batches of work.

Versatility in Cutting Diverse Shapes and Sizes:

With CNC laser cutting, fabricators can easily cut a wide range of shapes and designs, from simple circles to complex geometrical patterns. This flexibility opens up endless possibilities for custom fabrication projects, making it a preferred method for industries requiring bespoke components.

Reduced Material Waste:

The precision of CNC laser cutting means that cuts are made very close to one another, optimizing the use of materials and reducing waste. This efficiency not only lowers costs but also supports sustainable manufacturing practices by minimizing excess scrap metal.

Improved Safety and Reduced Labor Costs:

Since CNC laser cutting is automated and does not require direct contact with the material being cut, the risk of accidents and injuries is significantly lower compared to manual cutting processes. This automation also reduces the need for manual labor, lowering production costs.

Enhanced Quality of Cut:

The laser cutting process produces cleaner, smoother edges with minimal burring, reducing the need for secondary finishing processes. This quality finish is crucial for the aesthetic and functional aspects of the final product, particularly in industries where precision and appearance are paramount.

Flexibility with Materials:

While primarily used for steel fabrication, CNC laser cutting is also effective with a wide range of materials, including other metals, plastics, and composites. This adaptability allows fabrication shops to use a single machine for multiple materials, streamlining their operations.

Seamless Integration with CAD/CAM Software:

CNC laser cutting machines can be directly controlled by computer-aided design (CAD) and computer-aided manufacturing (CAM) software, allowing for seamless translation of digital designs into physical parts. This integration facilitates quick adjustments to designs and prototypes, accelerating the product development cycle.

In summary, CNC laser cutting's importance in steel fabrication lies in its ability to deliver high precision, efficiency, and versatility, making it a foundational technology in modern manufacturing. Its benefits extend beyond quality and speed, impacting cost, safety, and innovation in steel fabrication processes.