Menu

The Basics of Structural Steel Design: A Foundation for Building

Structural Steel Design Basics

Apr 3, 2024

Key Takeaways:

Structural steel design is pivotal in the architectural integrity and longevity of buildings and structures.

Understanding load, stress, and the types of steel used are fundamental in steel design.

Collaboration with seasoned steel fabricators like TratFab can elevate the precision and quality of any project.

The Basics of Structural Steel Design: A Foundation for Building

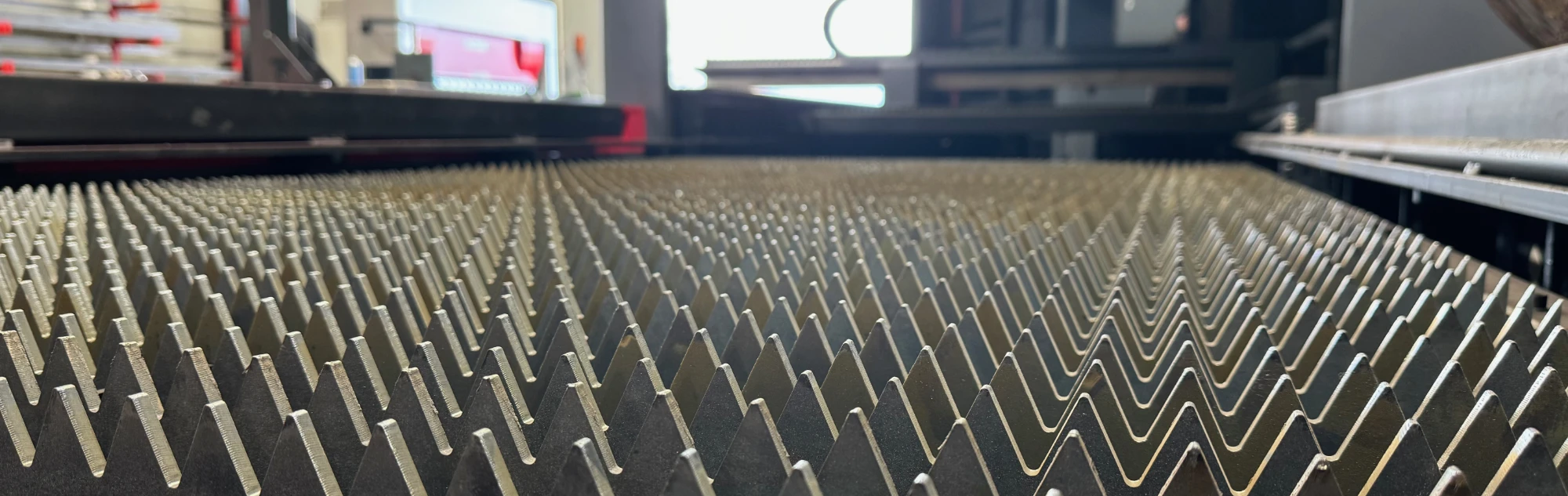

In the heart of Star, Idaho, lies a company that understands the bones of any sturdy construction: TratFab. As a leader in steel fabrication, we know that the essence of any enduring structure lies in its design. Structural steel design is more than just an initial step in the construction process; it's the blueprint of a building's life.

Understanding Structural Steel

Structural steel is a category of steel used for making construction materials in a variety of shapes. Its shape, form, and quality dictate the integrity of the construction. TratFab specializes in manipulating these materials to meet the specific needs of our clients, ensuring each project's foundation is as strong as the steel it's built with.

Why Structural Steel?

Strength, flexibility, and recyclability make structural steel a preferred choice for designers and architects. Its versatility allows for a wide range of architectural expressions and applications. From skyscrapers touching the clouds to sprawling bridges that span miles, structural steel is the backbone of modern infrastructure.

The Design Process

The design of structural steel involves a comprehensive understanding of engineering principles and the inherent properties of steel. Here are a few critical aspects:

Load and Stress Analysis: Every structure is subjected to loads, from the weight of the materials to environmental pressures like wind or earthquakes. Understanding these forces is crucial in determining the steel sections required to withstand them.

Type of Steel: Not all steel is created equal. The choice between hot-rolled steel, cold-formed steel, or weathering steel depends on the project's specific requirements, including environmental conditions and the desired aesthetic.

Connection Details: How steel members are connected greatly impacts the construction process and the structure's overall stability. Bolted connections and welding are among the techniques employed to ensure durability.

Sustainability in Design

With a growing emphasis on sustainability, structural steel design also considers the environmental impact. Steel is highly recyclable, which reduces waste and promotes a more sustainable construction practice. At TratFab, we prioritize eco-friendly methods without compromising on quality.

FAQs

Q: How long does the steel design process take? A: The complexity and scale of the project determine the timeframe. Our team works efficiently to balance thoroughness with deadlines, ensuring quality in every detail.

Q: How does TratFab ensure the quality of its steel designs? A: We adhere to strict industry standards and conduct rigorous quality checks throughout the design and fabrication phases.

Q: What types of projects can TratFab assist with? A: Our portfolio includes a wide range of projects, from commercial buildings and industrial facilities to custom installations.

In the world of construction, the design phase is where dreams start to take shape. At TratFab, we're committed to ensuring that these dreams not only rise from the ground but do so with integrity, safety, and innovation at their core. For more insights and to see how we can assist with your next project, visit us at Tratfab.com or call us directly at 208-571-5301. Your vision is our blueprint.